GMP compliant manufacturing facility

Hirono plant is a multipurpose manufacturing facility for highly potent APIs. The plant is compliant with category 5 containment and is capable of performing integrated manufacturing techniques including micronization.

Appearance of 3rd plant

itemProduct |

Equipment specificationsAPI & early phase drugs |

RemarkscGMP non-sterile |

|---|---|---|

| Facilities |

Containment Area 600 L(GL) Reactor x2 800L Glass Lined Reactor Filter Dryer (0.38m2) Material: Hastelloy C22 equivalent Micronization equipment: Spiral jet mill |

Multipurpose line Minimum mixing volume 50L Minimum mixing volume 50L Dryer filter capacity: 100L Micronization equipment Made by Food and Pharma Systems |

|

General production area 600L(GL)x1 |

Analytical laboratory management system isolated from production facilities |

|

| Containment level | Category 5 | Down to OEL: 0.1μg/m3 |

| Cleanliness level |

ISO class 8 c l ean room (Class 100,000 equivalent) |

|

| Temperature range | -15~100℃ | Reactor Jacket media: Brine |

| Building dimension |

Approx. 900m2 2 floor s teel ACL concrete |

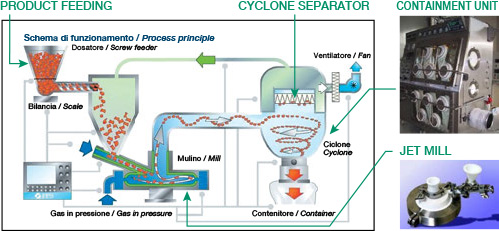

Milling and crushing of APIs

Various types of mills and crushers are available to meet API manufacturing requirements.

Counter jet mill

・Particle diameter 5 μm or less

Hammer mill

・Particle diameter 5 μm to 50 μm

Power mill

・Various types of screens are available.

・Round hole screen: 2 mm, 3 mm, and 5 mm

・Herringbone screen: 2 mm

Highly versatile spiral jet mill

- Milling particle diameter: 1 μm to 30 μm

- Production quantity: up to 30 kg/hr. 100 g to 100 kg/batch

- Simple structure that allows for easy cleaning Cleaning is possible in the isolator.

- Large particle sizes (up to 100 μm) are also possible. e.g. Q-MILL: up to 100 μm

- Can be expanded to handle milling at an extremely low temperature (-90°C)

- Prior testing of the milling capability can be performed(200 mg/batch)

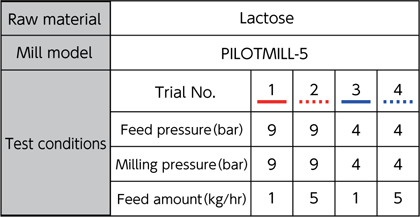

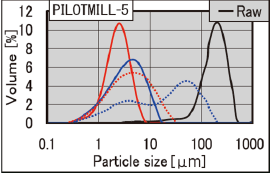

Particle diameters can be controlled by adjusting the feed pressure, milling pressure, and feed amount.

※ Cited from FPS milling machine catalog of CORRENS CORPORATION

Custom manufacturing facilities for pharmaceutical products

Various kinds of facilities and equipment can cover a wide range of scale.

We propose the process with the optimal facility according to the stage from development to commercial production.

Facility |

Scale |

QMS |

Special notes |

|---|---|---|---|

| Pilot production manufacturing | Capable of Scale-up checking (Hiratsuka plant) | ||

| 40~100L (GL) | nonGMP | Kilo lab facility | |

| 600~1,500L (GL) | nonGMP | 600L fluoride resin lined reactor | |

| API, Clinical trial API manufacturing | Capable of small-scale manufacturing (Miyazaki plant) | ||

|

1~20L(GL) 200~500L(GL/SUS/HAS) |

GMP | ISO class 8 clean room | |

| Clinical trial API manufacturing | Multi-line facility capable of a variety of reactions (Hirono plant) | ||

|

1,500L (GL/SUS) |

GMP |

1200L(SUS) low-pressure hydrogenation reactor (0.5MPa) 1,000 L (HC) super low-temperature reactor (-90℃) 2,000 L fluoride resin lined reactor ISO class 8 clean room |

|

| API manufacturing | Capable of small-scale manufacturing (Hirono plant) | ||

|

100~600L (GL/SUS) |

GMP |

Column purifying device ISO class 8 clean room |

|

| API manufacturing(1st plant) | 20 years of experience manufacturing APIs (Hirono plant) | ||

|

2,500~4,000L (GL/SUS) |

GMP |

Various mills (Counter jet mill, hammer mill and power mill) ISO class 8 clean room |

|

| Intermediate manufacturing(2nd plant) | Cost reduction through large scale continuous production (Hirono plant) | ||

|

6,000~10,000L (GL/SUS) |

GMP |

6,000L(SUS) low-pressure hydrogenation reactor (0.4MPa) Handling n -BuLi |

|

| Highly potent API manufacturing(3rd plant) | Category 5 high pharmacological active ingredient manufacturing facility (Hirono plant) | ||

| 600~800L (GL) | GMP |

Filter dryer (0.38m2) Spiral jet mill ISO class 8 clean room |

|

| API manufacturing(4th plant) | Large multipurpose APIs production facility since 2017 (Hirono plant) | ||

|

2,000~10,000L (GL/SUS) |

GMP |

6,000L(SUS) low-temperature reactor (-30℃)L Counter jet millL ISO class 8 clean room |

|

Please contact us about cost/case/technology/quality control

Inquiry formIntroducing examples of custom synthesis

Customer case studies