WPBG-300

Cas : 1801263-71-7

Plastics manufacturing

Photocurable

- Shows high stability (pot life) in monomer.

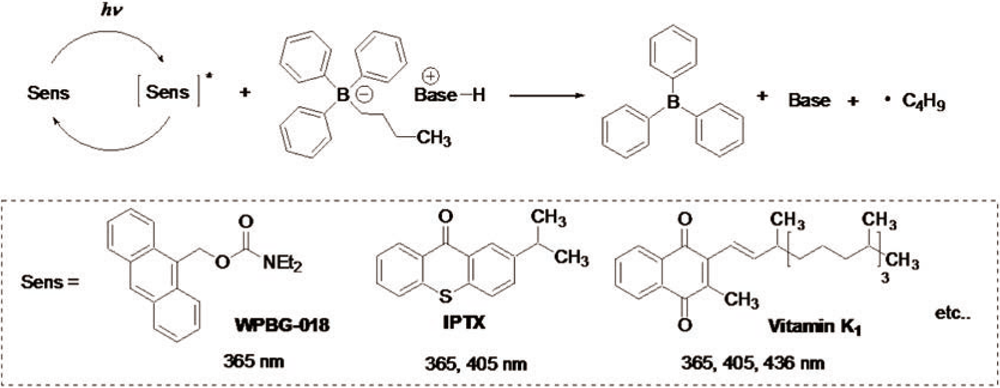

- Generates a strong base, biguanide (pKbH=31.8), upon irradiation.

- Can be exposed with sensitizer at 365 nm and longer wavelength.

- Can be employed with cross-linking agents such as thiol or anhydride.

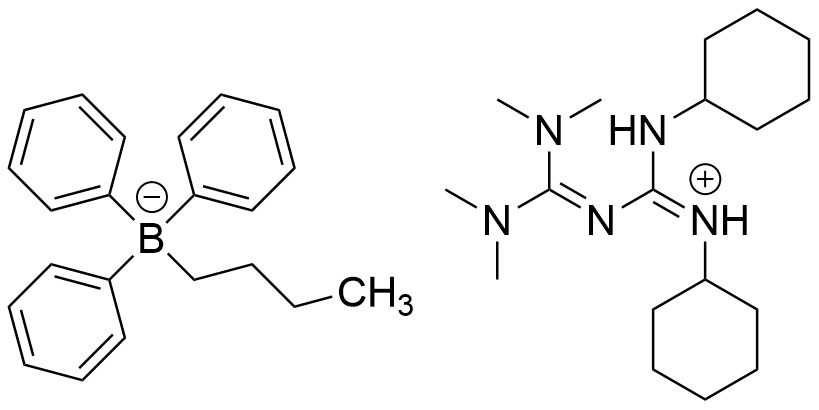

| Chemical name | 1,2-Dicyclohexyl-4,4,5,5-tetramethylbiguanidium n-butyltriphenylborate |

|---|---|

| CAS RN® | 1801263-71-7 |

| Molecular weight | 621.75 |

Physical characteristics

| Color Appearance |

white powder |

|---|---|

| Melting point/freezing point | 115℃ |

| Solubilities | water : slightly soluble. |

| TG-DTA | weight loss from 203℃ |

| Solubility | (g/solv. 100 g)

|

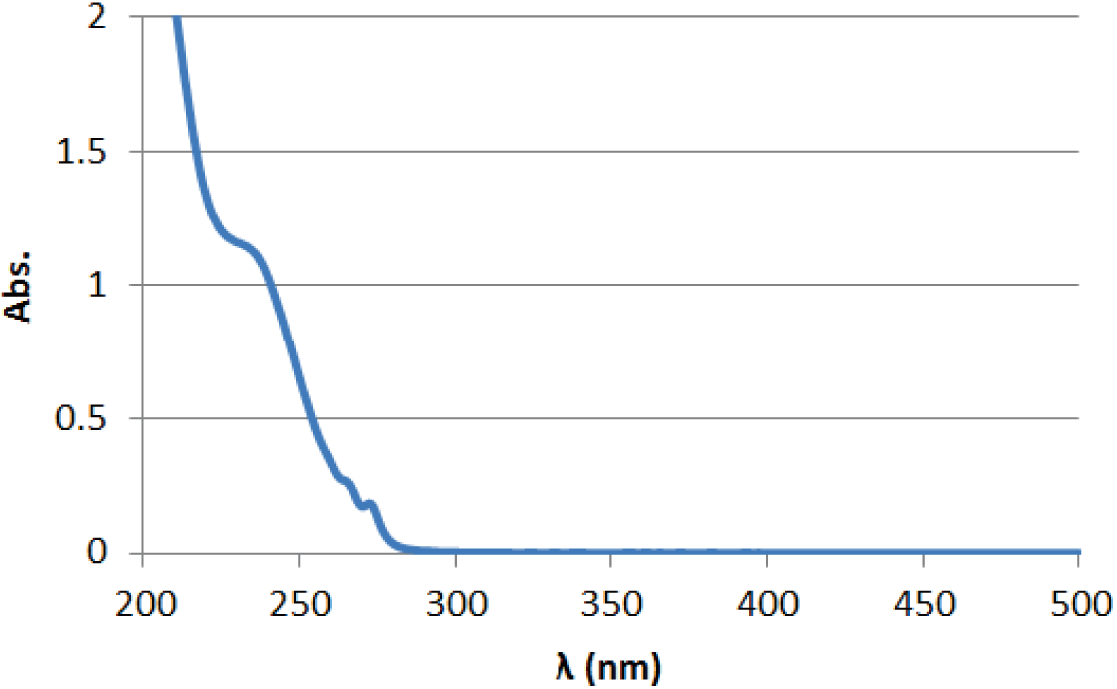

UV(0.02 mg/mL in CH3CN)

Absorption maximum

197 nm(ε=79000) 254 nm(ε=14000) 365 nm(ε=0)

Related laws and regulations

| TSCA | Not Listed |

|---|---|

| EINECS | Not Listed |

| REACH | Not Listed |

Packaging

- 5g

Mechanism of base generation

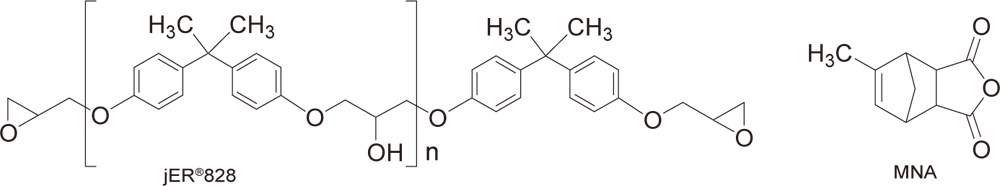

Example of Use 1Anionic UV curing of epoxy oligomer × polyfunctional thiol

Conditions

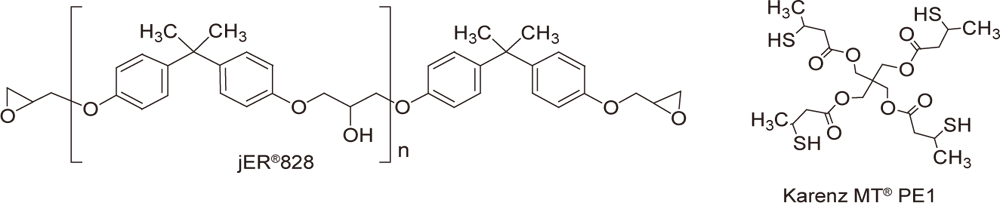

| Preparation | Mix 1-5 parts of WPBG 300, 0.2-1 part of 2-isopropylthioxanthone (0.2 equivalent amount to WPBG), and 100 parts of jER®828 (epoxy equivalent of 185, Product of Mitsubishi Chemical Corporation), and heat or use a diluent to promote dissolution. Mix 70 parts of KarenzMT®PE1 (SH equivalent of 138.5, Product of Showa Denko K.K.) at room temperature. |

|---|---|

| Stability of composition as pot life (period in which the viscosity does not exceed the twice of the initial viscosity) | 1 month (10°C), 1 week (25°C), and 3 days (40°C) |

| Exposure | Irradiation for 10 seconds (Illuminance: 5mW/cm2 (254 nm), 100 mW/cm2 (365 nm), and 261 mW/cm2 (405 nm)) |

Example of Use 2Anionic UV curing of epoxy oligomer × acid anhydride

Conditions

| Preparation | Mix 3-10 parts of WPBG-300, 0.6-2 parts of 2-isopropylthioxanthone (0.2 equivalent amount to WPBG), and 100 parts of jER®828 (epoxy equivalent of 185, Product of Mitsubishi Chemical Corporation), and heat or use a diluent to dissolve. Mix 50 parts of methyl-5-norbornene-2,3-dicarboxylic anhydride (Product of FUJIFILM Wako Pure Chemical Corporation) at room temperature. |

|---|---|

| Stability of composition as pot life (period in which the viscosity does not exceed the twice of the initial viscosity) | 1 month (10°C), 1 week (25°C), and 3 days (40°C) |

| Exposure | Irradiation for 10 seconds (Illuminance: 5mW/cm2 (254 nm), 100 mW/cm2 (365 nm), and 261 mW/cm2 (405 nm)) |

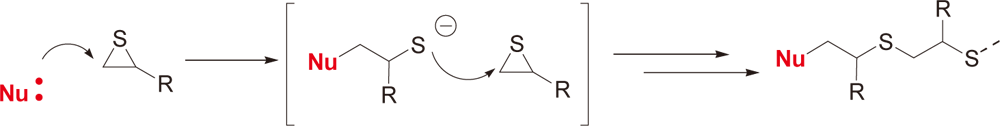

Example of Use 3Anionic UV curing of episulfide

Conditions

| Preparation | Mix 1-5 parts of WPBG-300 and 0.2-1 part of 2-isopropylthioxanthone (0.2 equivalent amount to WPBG) in 20 parts of γ-butyrolactone and mix hydrogenated bisphenol A type episulphide (episulphide equivalent of 220). |

|---|---|

| Stability of composition as pot life (period in which the viscosity does not exceed the twice of the initial viscosity) | 1 month (10°C), 1 week (25°C), and 3 days (40°C) |

| Exposure | Irradiation for 10 seconds (Illuminance: 5mW/cm2 (254 nm), 100 mW/cm2 (365 nm), and 261 mW/cm2 (405 nm)) |

Contact us for more details.

We are waiting for questions and requests on products.