Aichi plant

- LocationToyohashi, Aichi Pref.

- Site Area176,000 m2

- Number of employees80 people

- Beginning of operation2004

- CertificationISO9001、ISO14001

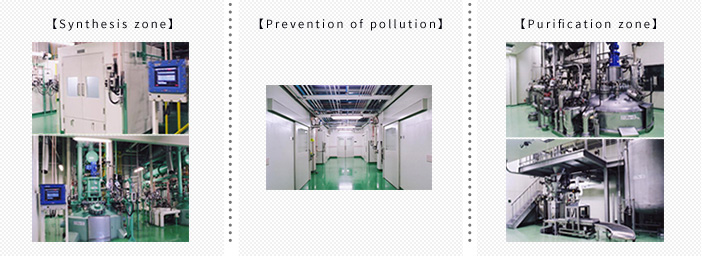

- 3 direct production plant that is suitable for large scale production of Specialty Chemicals

- Realizing highly efficient production and labor efficiently by large automated reaction facilities

- Achieving manufacturing management with advanced prevention of pollution such as zone partitioning

- Introducing multipurpose reaction facilities corresponding to wide range of reaction conditions

- Shortening of production switching time by the automatic liquid chemical transport switching system

- Consistent development system at the same site

Main facilities

- Clean room for GMP (Class 100,000)

Reactor(GL), whizzer(Hastelloy), conical dryer(GL) - Multipurpose equipment

- Reactor(GL, SUS)200~10,000L

- Autoclave, Ultra-low temperature reactor(-80℃~)

- Centrifuge

- Filtration machine

- General-purpose clean room

- Liquid preparation equipment under the metal management

- Shading equipment

- Dryer (Conical, vacuum dryer, etc.)

- Analysis equipment NMR(400MHz), FT-IR, ICP/MS, ICP/OES

- Ion cromatography, GPC others

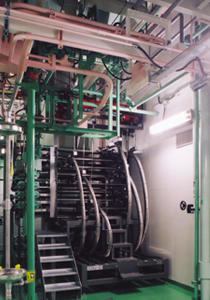

Low temperature reactor (-80℃)

Liquid chemical transport switching system

Solvent XY router

・This router charges each solvent automatically.

・It connects the solvent tank and the reactor freely.

Drug Solution XY reactor

・It connects between reactors freely.

・You can select the switching of the line either automatic or manual.

・You can transport the slurry of up tp 30 %.

Zones partitioning

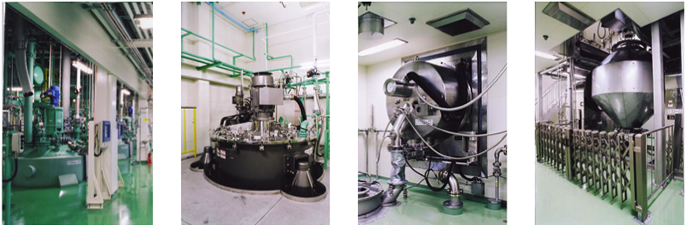

Facilities for large production

| Reactor | 6000~10000L (GL/SUS316L) 10 group |

|---|---|

| Centrifuge | 55B (SUS316L/Hastelloy®) 4 group |

| Dryer | 5000L (GL Conical) 2 group |

Facilities for small/medium production

| Reactor | 300~5000L (GL/SUS316L) 7 group |

|---|---|

| Centrifuge | 30、42B (SUS316L/Hastelloy®) 5 group |

| Dryer | 500L, 3000L (GL Conical) 2 group |