Customer case studies

Example 4:Customer D (foreign pharmaceutical manufacturer)

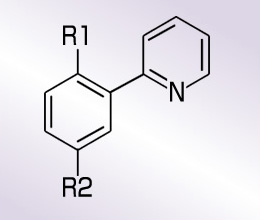

Foreign customer D manufacturing pharmaceutical products considered reducing the cost for API they were developing. The customer focused on our synthetic method of 2-pyridine derivative as a manufacturing method of an intermediate.

Cross-coupling reactions, Ullmann reactions or Suzuki-Miyaura coupling reactions are generally used for synthesizing 2-pyridine derivatives. However, these synthetic methods require expensive metal catalyst or reagents, and finished product cost is high due to metal removal.

Product:Intermediate

・Expensive metal catalysts and regents are required to construct the skeleton of 2-pyridine.

・The process to remove metal is required.

Succeed in reducing 55% of the cost by introducing our original synthetic method for pyridine derivative.

Detail for customer case studies

Example 3:Customer C (pharmaceutical manufacturer)

Customer C engaged us to consult on the production of an API after a long period of inactivity (demand for this specific API resurfaced).

We examined the API and its crystallization process. As a result, we confirmed the following problems.

Product:API

Each crystal has different solubility, bioavailability and stability ranges depending on its shape, and the medicinal effect of pharmaceutical products may change based on shape. The precipitation and transition of stable crystals must be prevented because the object is metastable crystal* in this case.

Ensure the requisite quality by identifying the unknowns of crystallization based on our accumulated knowledge.

Detail for customer case studies

Example 2:Customer B (pharmaceutical manufacturer)

Customer B (pharmaceutical company) considered outsourcing of essential APIs as a new business development with us.

Through repeated meeting with company B, we performed a crystallization examination based on the existing information. As a result, it was confirmed that the crystallization process of the compound had the following problem.

Product:API

Since the filterability of crystal is lower than the previous assumption, the filtrate cannot pass through for several hours. Therefore, the productivity is very low.

Succeed in achieving the scale-up in a shorter time than expected by solving the increasing filterability.

Detail for customer case studies

Example 1:Customer A (industrial materials manufacturer)

Customer A is manufacturing highly-functional industrial films. Customer A had a potential business issue of reducing the manufacturing cost and improving the profitability and price competitiveness. Accordingly, they considered outsourcing the production of organic compounds. Then, we had an inquiry from them.

To examine the crystallization process of the compound, we performed crystallization while changing solvent ratios, temperature, stirring conditions and so on, and investigated the quality and filterability. As a result, we confirmed that the former process had the following problems.

Product:Film material

・The content of the obtained object from crystal is less than expected and there are much impurities (reaction by-products).

・Since it takes time to separate into solid and liquid after crystallization, the yield is poor.

Succeed in reducing the manufacturing cost of 50 million yen per year by identifying the problem of crystallization process and improving it.

Detail for customer case studies

Please contact us about cost/case/technology/quality control

Inquiry form