Customer case studies

Example 2:Customer B (pharmaceutical manufacturer)

Product:API

Succeeded in rapidly scaling the production by increasing the filterability of the desired product.

Customer B (pharmaceutical manufacturer) considered consigning production of an essential API through new product development.

Based on the data provided by company B, we performed an examination of the crystallization process. We determined that the crystallization process of the compound had the following

・Since the filterability of crystal is lower than the previous assumption, the filtrate cannot pass through for several hours. Therefore, throughput was very low.

Equipment used for this case

Equipment used for this case

We found a novel solution based on the latest research and our experience in crystallization and filtration.

Since the filterability was very low, we postulated that the scale-up from laboratory to production scale would be very difficult and we could not manufacture in our plant even if company B provided the reaction scheme. In addition, due to quality and crystal polymorphism issues, we were not permitted to change the solvent composition.

Therefore, we repeatedly performed the crystallization experiment while changing the mixing method, temperature, stirring condition and so on of the solvent. As a result, we succeeded in improving the process with Ostwald ripening through the following study stages.

Examination process

- As a result of solubility investigation, we confirmed that crystal size was highly dependent on solvent temperature.

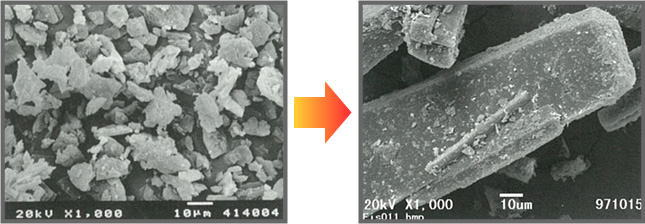

- As a result of analysis of the crystal form and particle size distribution of the API, we considered that we can control the form by controlling temperature. We confirmed that the thickness of capillary crystals (several μm) increased substantially and the filterability improved remarkably.

Example: Succeeded in obtaining the crystals with high filterability by Ostwald ripening

Result

As a result of controlling the crystal form with Ostwald ripening, it improved so that it could be filtered easily by a centrifugal filter. By this method the quality, quantity, price and delivery date of the product were in line with requirements from company B. Therefore, company B could advance the introduction to market of a new pharmaceutical product on schedule.

Our custom manufacturing /synthesis makes a difference

We have vast experience in researching the production methods of various raw materials for high-performance products such as APIs/intermediates, ink dyes, electronic materials, photographs, printing plates and films with a wide range of businesses of FUJIFILM group. We have created a database of our crystallization experience that enables us to search for the optimum condition effectively.

Solutions for company B

- Succeeded in commercial production considered to be difficult in a short time.

- Support the introduction to market of a new pharmaceutical product within expected QCD.

Please contact us about cost/case/technology/quality control

Inquiry form