Customer case studies

Example 1:Customer A (industrial materials manufacturer)

Product:Film material

Succeeded in reducing the manufacturing cost by 50 million yen per year by identifying a problem in the crystallization process and improving it.

Customer A is manufacturing highly-functional industrial films. Customer A sought to reduce the manufacturing cost of the film and improve profitability and price competitiveness. Accordingly, customer A considered outsourcing the production of organic compounds in the film and reached out to us.

To examine the crystallization process of the compound, we performed multiple crystallizations while changing solvent ratios, temperature, stirring conditions and so on, and investigated the quality and filterability of the product. As a result, we confirmed that the former process had the following problems.

・The content of the obtained object from crystal was less than expected and there were much impurities (reaction by-product). Though the target value of the content of impurities was 1.5% or less, it reached approximately 1.8%.

・Since it took time to separate into solid and liquid after crystallization, the yield was poor.

Centrifuge used for separating solid and liquid

Centrifuge used for separating solid and liquid

We proposed the optimum manufacturing condition with speed and precision by examining our existing database of reaction conditions.

To solve the problem of customer A, we proposed changing the solvent for crystallization. We selected the optimum solvent using the following steps.

Process for solvent selection

- As for the solvent which tended to dissolve the impurities and not to dissolve the object, we selected five applicable solvents from our original database.

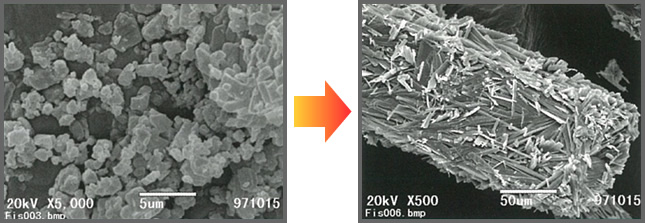

- After we narrowed the 5 solvents by the objective solubility investigation, we performed the crystallization examination. We selected the solvent capable of forming a crystal with high filterability (large particle diameter, less fine particles, aspect ratio=1: 1 or near).

Successful case: To obtain the crystal with high filterability by changing the solvent based on our database

Results against the problems

As a result of the pilot production with the solvent, we succeeded in shortening the filtrating time as follows.

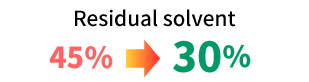

In addition, succeeded in reducing the amount of residual solvent and the drying time owing to high filterability.

Finally, our process resulted in the following performances. We could supply the requested organic compound with the appropriate quality, amount and delivery date, which contributed to solving the business issues of company A.

Our custom manufacturing /synthesis makes a difference

We have experience in researching the production of various raw materials for high-performance materials such as APIs/intermediates, ink dyes, electronic materials, photographs, printing plates and films with a wide range of businesses of FUJIFILM group. Our database of crystallization mechanics has been developed over decades of experimentation. Searching this database willenable us to locate the optimum condition effectively.

Performances for business issues of company A

- Succeeded in reducing lead time to one third

- Succeeded in reducing the cost of 50 million yen per year

Please contact us about cost/case/technology/quality control

Inquiry form