Advanced scale-up technology

Scale-up from laboratory to production

The scale-up technology gained by manufacturing more than 500 types per year enables us to scale-up from laboratory to production. Therefore, we can supply the products in a shorter time.

Scale-up from laboratory to production

The scale-up technology gained by manufacturing more than 500 types per year enables us to scale-up from laboratory to production. Therefore, we can supply the products in a shorter time.

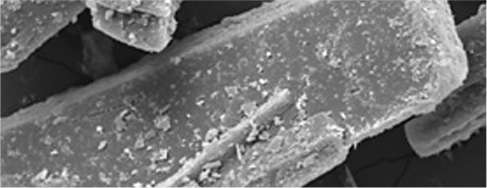

Control of crystal shapes in crystallization

The optimum conditions can be efficiently searched for in a database containing abundant information on the crystallization of organic chemical compounds.

Control of crystal shapes in crystallization

The optimum conditions can be efficiently searched for in a database containing abundant information on the crystallization of organic chemical compounds.

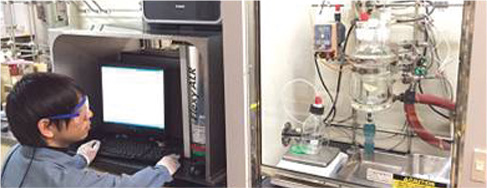

Thermodynamic simulation

We measure the heating value by a reaction calorimeter. The simulation is performed based on the data of the actual reactor.

Thermodynamic simulation

We measure the heating value by a reaction calorimeter. The simulation is performed based on the data of the actual reactor.

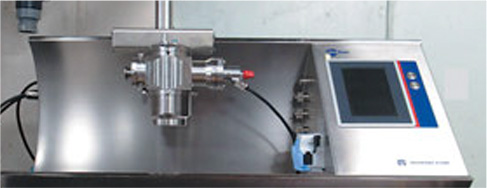

Small-scale examination for milling condition

Our test mill can simulate operations at a 10g scale or smaller. The appropriate mill type and conditions for achieving target particle size can be found.

Small-scale examination for milling condition

Our test mill can simulate operations at a 10g scale or smaller. The appropriate mill type and conditions for achieving target particle size can be found.

Scale-up simulation of crystal filtration

Filtration with production equipment is simulated by using centrifugal filtration test equipment. Problems with filtration properties can be improved using our crystallization technology.

Scale-up simulation of crystal filtration

Filtration with production equipment is simulated by using centrifugal filtration test equipment. Problems with filtration properties can be improved using our crystallization technology.

Scale-up simulation of crystal drying

Short time consistent quality drying conditions are determined by the use of conical drying test equipment. For instance, stable upscaling is achieved through continuous rotation to prevent conglomerate crystallization and by using mechanical impacts to check for crystal dislocation.

Scale-up simulation of crystal drying

Short time consistent quality drying conditions are determined by the use of conical drying test equipment. For instance, stable upscaling is achieved through continuous rotation to prevent conglomerate crystallization and by using mechanical impacts to check for crystal dislocation.

Please contact us about cost/case/technology/quality control

Inquiry formIntroducing examples of custom synthesis

Customer case studies