Equipment for special reactions

Super low-temperature reaction

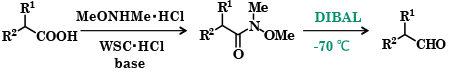

Transformation of carboxylic acid derivatives to aldehyde via Weinreb amide

Corey-Fuchs alkyne synthesis

1000 L super low temperature reaction reactor

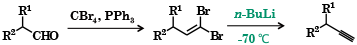

Low-pressure hydrogenation reaction

Catalytic hydrogenation reaction by using a metal catalyst

1200 L low-pressure hydrogenation reaction reactor

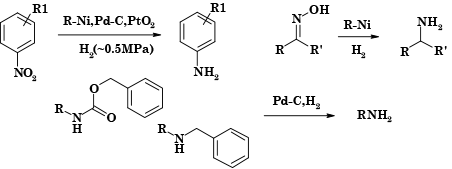

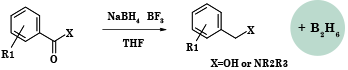

Safe scale-up of borane reduction

Implementation example 1 : Using 6000 L

Implementation example 2 : Using 9000 L

Characteristics of generated diborane gas

・Risk of spontaneous combustion and explosion

・Toxicity level hazardous to human health

Production scale can be increased through quenching and controlling diborane gas generation

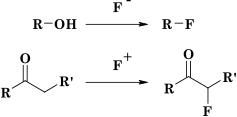

Fluorine corrosion resistant equipment

Reactions using various fluorinating agents are possible

Capable of handling processes with risk of GL corrosion due to hydrofluoric acid generation

Although separation of a CF3 group is not easy, fluoride ion may be eliminated when an electron donating group exists via an aromatic ring.

GMP compliant 2,000 L fluororesin lined reactor (with carbon condenser)

Please contact us about cost/case/technology/quality control

Inquiry formIntroducing examples of custom synthesis

Customer case studies