WPBG-266

Cas : 1632211-89-2

Plastics manufacturing

Photocurable

- Generates a strong base, biguanide (pKbH=31.8), in high quantum yield upon irradiation.

- Shows high solubility to various solvents.

- Has radical initiation capability.

- Is optimal as catalyst for sol-gel method.

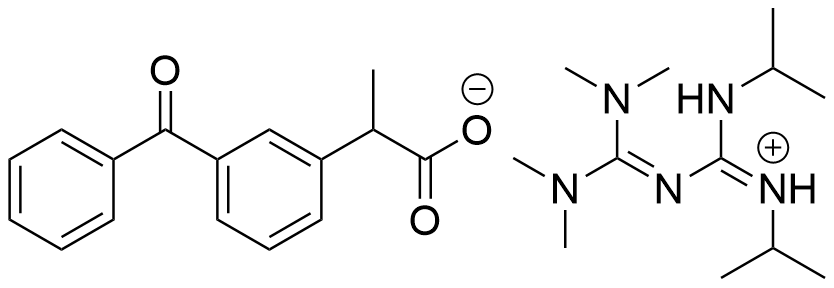

| Chemical name | 1,2-Diisopropyl-3-[Bis(dimethylamino)methylene]guanidium 2-(3-benzoylphenyl)propionate |

|---|---|

| CAS RN® | 1632211-89-2 |

| Molecular weight | 495.67 |

Physical characteristics

| Color Appearance |

white powder |

|---|---|

| Melting point/freezing point | 115℃ |

| Solubilities | water, acetone, methanol, 1-methyl-2-pyrrolidone : freely soluble. PGMEA (1-methoxy-2-propyl acetate) : soluble. |

| TG-DTA | weight loss from 191℃ |

| Solubility | (g/solv. 100 g)

|

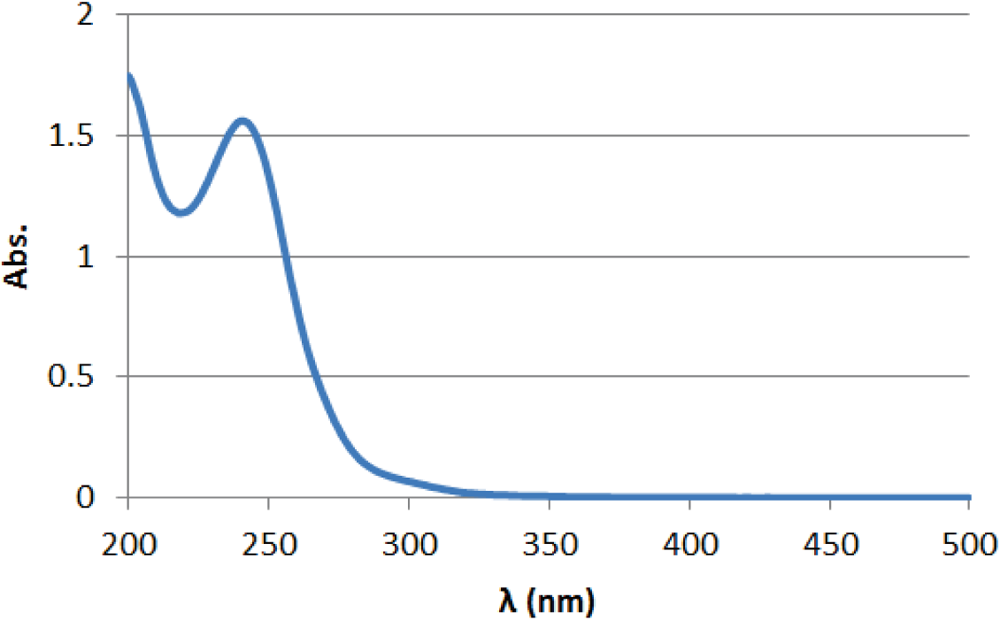

UV(0.02 mg/mL in CH3CN)

Absorption maximum

240 nm (ε=34000) 254 nm (ε=25400) 365 nm (ε=80)

Related laws and regulations

| TSCA | Not Listed |

|---|---|

| EINECS | Not Listed |

| REACH | Not Listed |

Packaging

- 5g

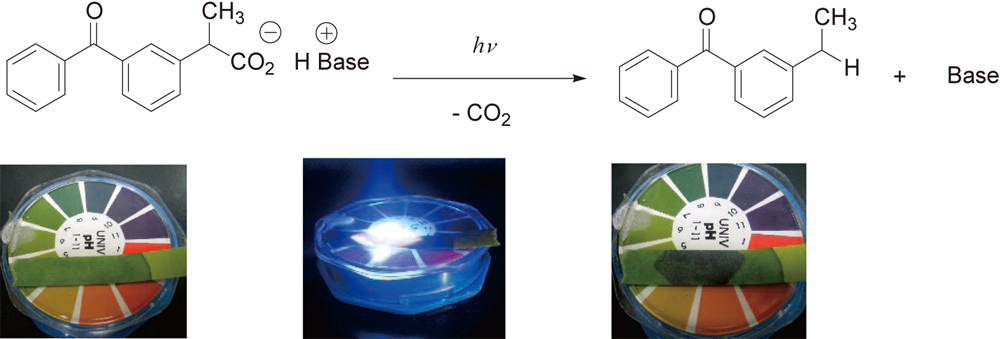

Mechanism of base generation

Immerse pH-test paper in the aqueous solution, irradiate UV, and the transition to the basicity is confirmed visually.

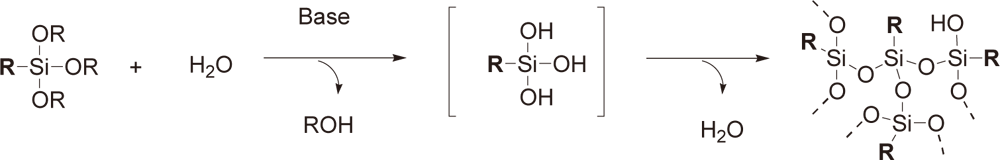

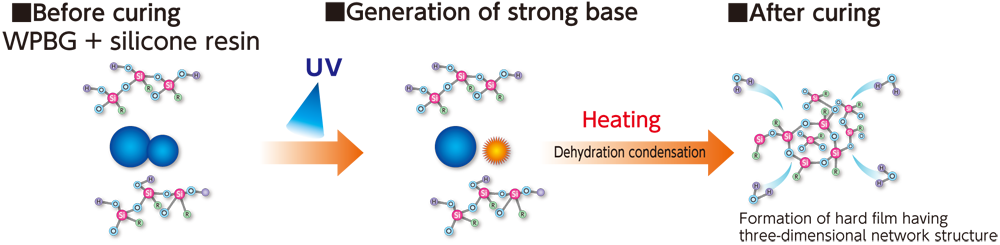

Sol-gel method

The Sol-gel method is a technique to form metal oxides by hydrolysis and condensation polymerization of alkoxysilane, etc. It is generally well known that both hydrolysis and condensation polymerization proceed promptly when bases are used.

WPBG-266 is optimal for the curing of the silanol compounds formed by hydrolysis of trisubstituted alkoxysilyl compounds. The silanol compounds formed by hydrolysis of tetrasubstituted alkoxysilyl compounds tend to gel easily, therefore they must be handled carefully.

Example of Use 1Anionic UV curing of methyl/phenyl silicone resin

KR-300 is a high-temperature-curing-type silanol polymer having methyl and phenyl groups on a silicon atom.

Curing temperature can be decreased by using WPBG-266 combined with light exposure.

Conditions

| Composition | 5 parts of WPBG-266, 100 parts of 2-isopropylalkohol and 100 parts of KR-300 (Product of Shin-Etsu Chemical Co., Ltd.) are blended. |

|---|---|

| Film-forming | Glass plate (i) Spin coat: 500 rpm/5 seconds → 1000 rpm/30 seconds (ii) Pre-bake: 80°C/1 minute Film thickness: approximately 10 μm |

| Exposure | Irradiate for 10 seconds (Illuminance: 5 mW/cm2 (254 nm), 100 mW/cm2 (365 nm), and 261 mW/cm2 (405 nm)) |

| Post-exposure bake | 150°C/5 minutes |

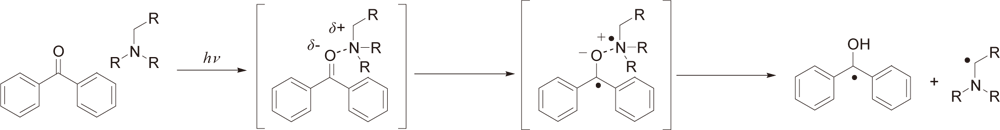

Mechanism of radical generation from WPBG-266.

WPBG-266 is able to generate two different active species a base and a radical by light irradiation. radical with light irradiation.

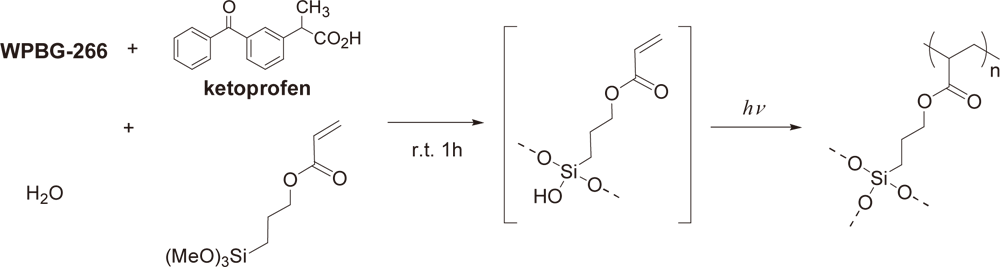

Hydrolysis using WPBG-266 with ketoprofen (a carboxylic acid which decarboxylates by light irradiation)

The hydrolysis of silane coupling agents in the presence of WPBG-266, ketprofen and water will be accelated by the lower pH (acidic conditions). The silanol body thus obtained is not isolated and the system moves to basicity if UV is irradiated as it is. Therefore, cured material can be formed from one component.

Example of Use 2UV curing using radical polymerization and sol-gel method together (organic and inorganic hybrid)

Conditions

| Preparation | Mix 15 parts of WPBG-266, 5 parts of ketoprofen, 245 parts of (3-acryloxy)propyltrimethoxysilane, and 54 parts of water and stir the solution until it becomes homogeneous at the room temperature. |

|---|---|

| Film-forming | After application with a wire bar, prebake at 80ºC/1 minute. Film thickness: approximately 10-20 μm |

| Exposure | Under N2 flow, irradiate for 30 seconds (Illuminance: 5mW/cm2 (254 nm), 100 mW/cm2 (365 nm), and 261 mW/cm2 (405 nm)) |

| Post-exposure bake | None |

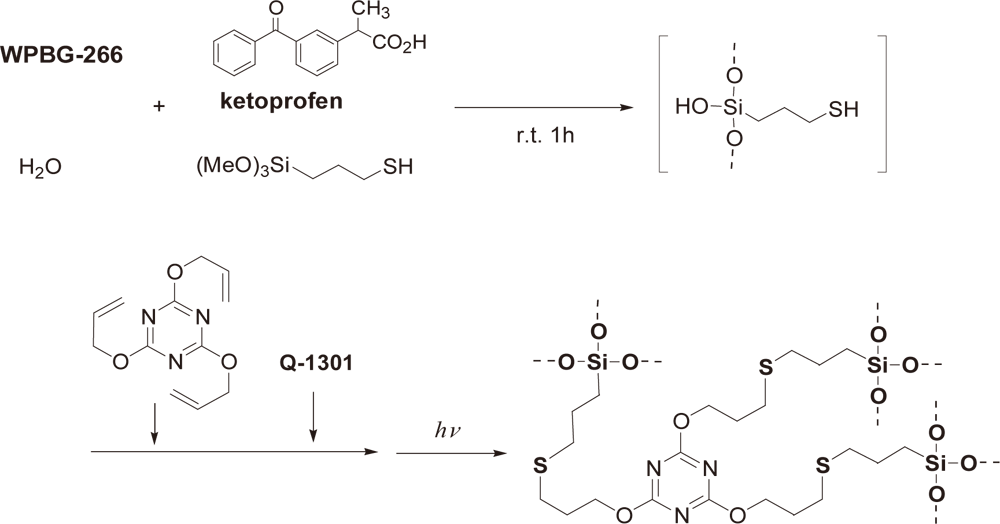

Example of Use 3UV curing using thiol-ene reaction together with the sol-gel method (organic and inorganic hybrid)

Conditions

| Preparation | Mix 15 parts of WPBG-266, 5 parts of ketoprofen, 196 parts of (3-mercaptopropyl)trimethoxysilane, and 27 parts of water and stir the solution until it becomes homogeneous at the room temperature. Add 83 parts of 2,4,6-tris(alyloxy)-1,3,5-triazine and 0.3 part of polymerization inhibitor Q-1301 (Product of FUJIFILM Wako Pure Chemical Corporation) and mix. |

|---|---|

| Film-forming | After application with a wire bar, prebake at 80ºC/1 minute. Film thickness: approximately 10-20 μm |

| Exposure | Irradiate for 10 seconds (Illuminance: 5mW/cm2 (254 nm), 100 mW/cm2 (365 nm), and 261 mW/cm2(405 nm)) |

| Post-exposure bake | None |

Reference

K. Arimitsu, A. Kushima, et al., Polymer Preprints, Japan, 2005, 54, 1357.

K. Arimitsu, A. Kushima, R. Endo, J. Photopolym. Sci. Technol., 2009, 22, 663.

K. Arimitsu, R. Endo., Chem. Mater. 2013, 25, 4461-4463.

K. Arimitsu, Journal of Synthetic Organic Chemistry,Japan 2012,70,508.

Contact us for more details.

We are waiting for questions and requests on products.