RAFT-013

RAFT agent for mass production

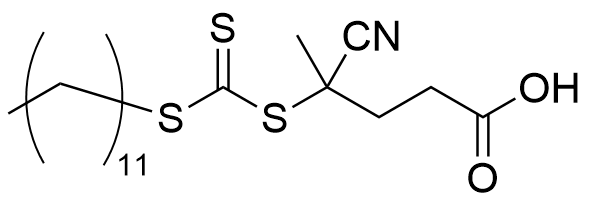

This is a one-terminal reaction type RAFT agent that is suited to the polymerization of methacrylate. It can also be used for polymerization of styrene and acrylate.

- One-terminal extension type

- Applicable to acrylate, methacrylate, etc.

| Chemical name | 4-Cyano-4-[(dodecylsulfanylthiocarbonyl)sulfanyl]pentanoic acid |

|---|---|

| CAS RN® | 870196-80-8 |

| Molecular weight | 403.67 |

Physical properties

| Appearance | Pale yellow - brown,crystalline powder - powder |

|---|---|

| Odor | Slightly sulfur odor |

| Melting point | 64~68℃ |

| Solubility |

Ethanol, acetone, PGME, PGMEA: Soluble Water, hexane: Insoluble |

Storage conditions

| Storage conditions | Store away from sunlight in well-ventilated place at room temperature(preferably cool) |

|---|

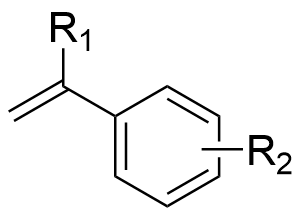

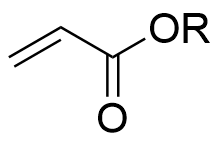

Monomer compatibility

Styrene〇

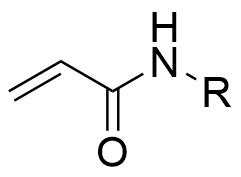

Acrylate〇

Acrylamide〇

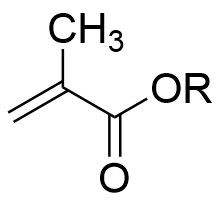

Methacrylate〇

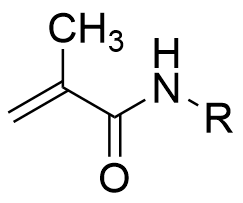

Methacrylamide〇

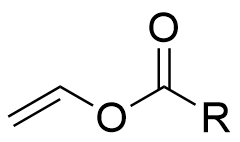

Vinyl ester×

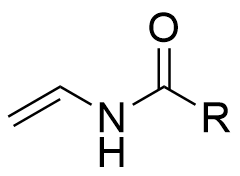

Vinylamide×

Related items

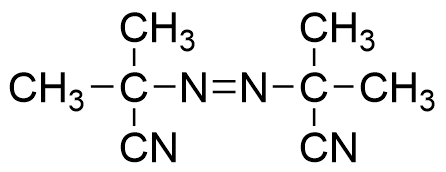

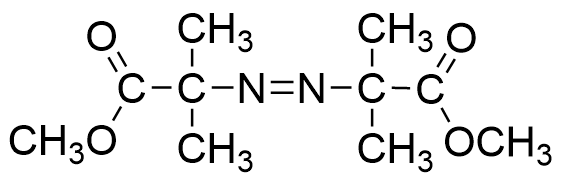

V-601

- Non-nitrile azo initiator as an alternative to AIBN

- With equivalent polymerization activity of AIBN. Efficiency of polymerization rises in alcohol solvents

- 10 Hour half-life decomposition temperature: 66℃

View

View

Contact us for more details.

We are waiting for questions and requests on products.