WPBG-345

Cas : 2073916-67-1

Plastics manufacturing

Photocurable

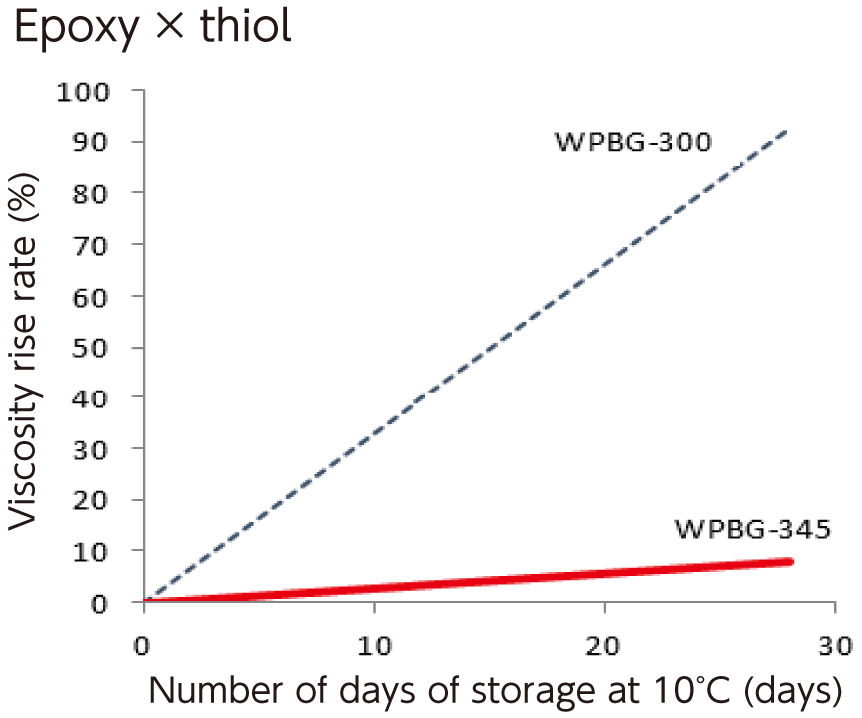

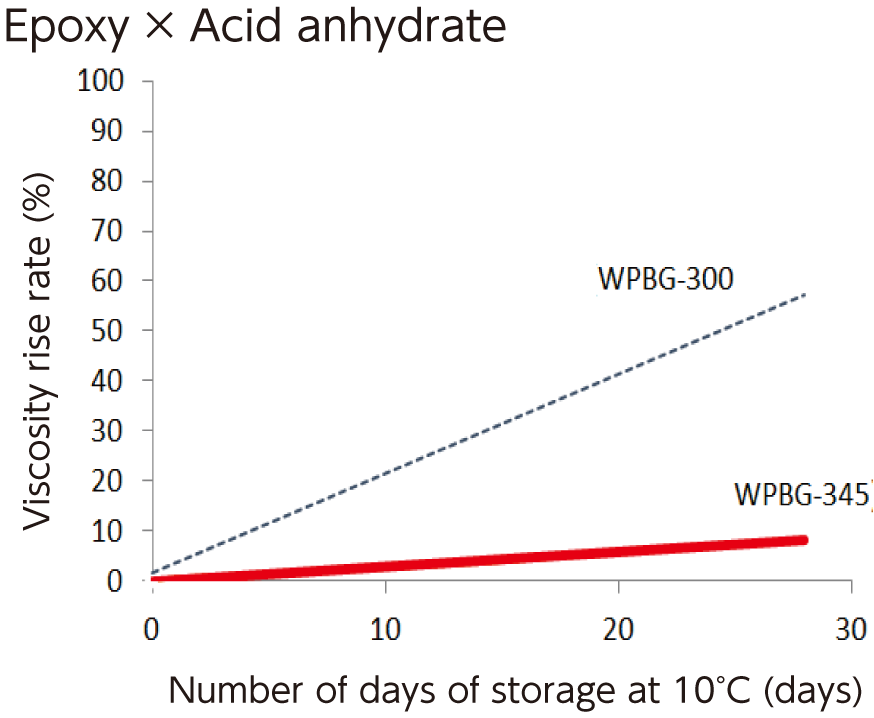

- Shows high stability (pot life) in various compositions (epoxy × thiol and epoxy × acid anhydride).

- Generates a strong base, biguanide (pKbH =31.8), upon irradiation.

- Can be exposed with sensitizer at 365 nm and longer wavelength.

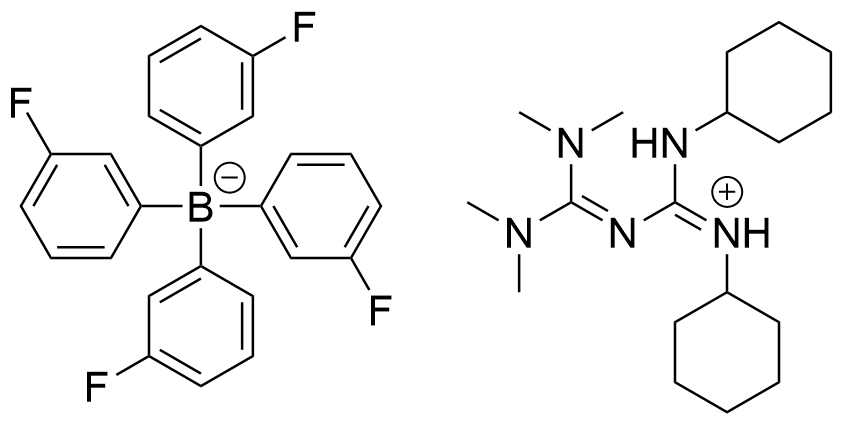

| Chemical name | (Z)-{[Bis(dimethylamino)methylidene]amino}-N-cyclohexyl(cyclohexylamino)methaniminium tetrakis(3-fluorophenyl)borate |

|---|---|

| CAS RN® | 2073916-67-1 |

| Molecular weight | 713.70 |

Physical characteristics

| Color Appearance |

nearly white crystals |

|---|---|

| Melting point/freezing point | 138℃ |

| Solubilities | water, diisopropyl ether : practically insoluble,or insoluble. |

| TG-DTA | weight loss from 231℃ |

| Solubility | (g/solv. 100 g)

|

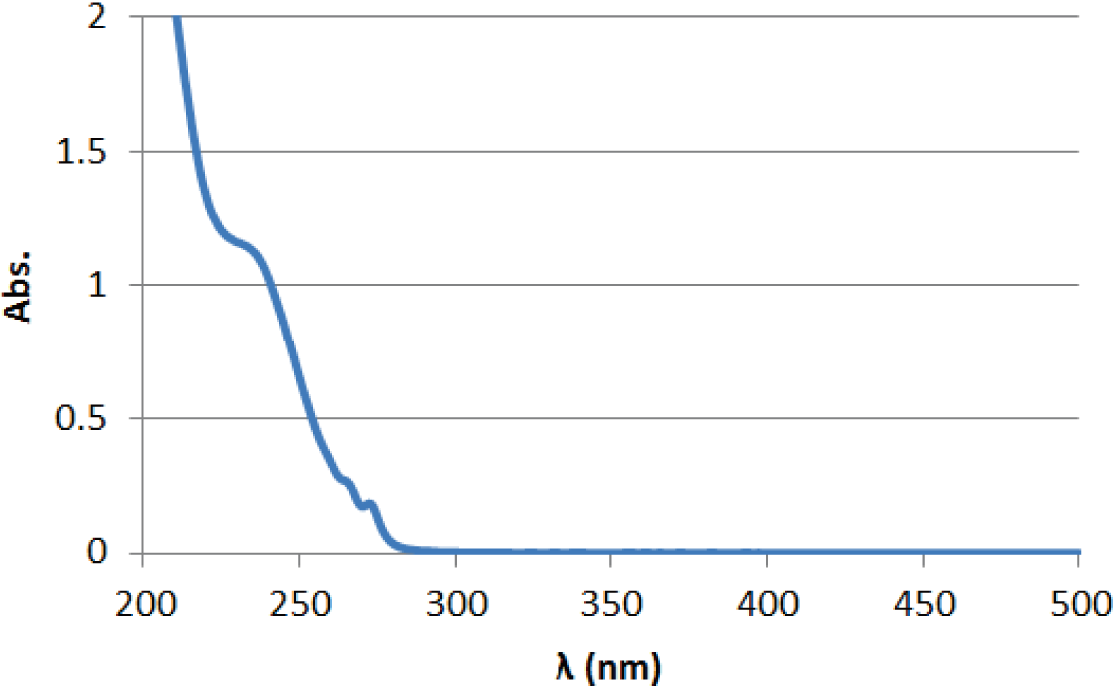

UV(0.02 mg/mL in CH3CN)

Absorption maximum

197 nm(ε=118000) 254 nm(ε=15500) 365 nm(ε=15)

Related laws and regulations

| TSCA | Not Listed |

|---|---|

| EINECS | Not Listed |

| REACH | Not Listed |

Stability of compositions as pot life

●Possible to use sensitizer in order to irradiate @365 nm and longer wavelength.

●higher stability of pot-life than WPBG-300.

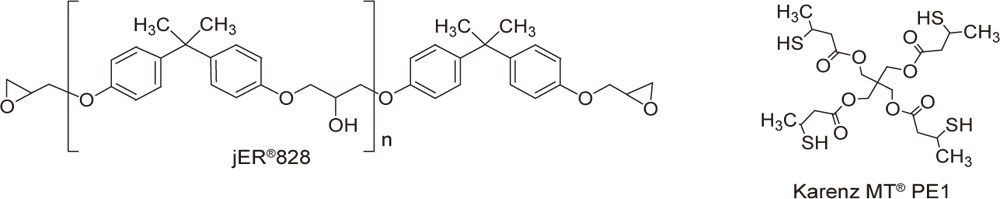

Example of Use 1Anionic UV curing of epoxy oligomer × polyfunctional thiol

Conditions

| Preparation | Mix 3-10 parts of WPBG-345, 0.6-2 parts of 2-isopropylthioxanthone (0.2 equivalent amount to WPBG), and 100 parts of jER®828 (epoxy equivalent of 185, Product of Mitsubishi Chemical Corporation), and heat or use a diluent to promote dissolution. Mix 70 parts of KarenzMT®PE1 (SH equivalent of 138.5, Product of Showa Denko K.K.) at room temperature. |

|---|---|

| Stability of components as pot life (period in which the viscosity does not exceed the twice of the initial viscosity) | 2 month or more (10°C), 3 weeks (25°C), and 3 days (40°C) |

| Exposure | Irradiation for 10 seconds (Illuminance: 5mW/cm2 (254 nm), 100 mW/cm22 (365 nm), and 261 mW/cm2 (405 nm)) |

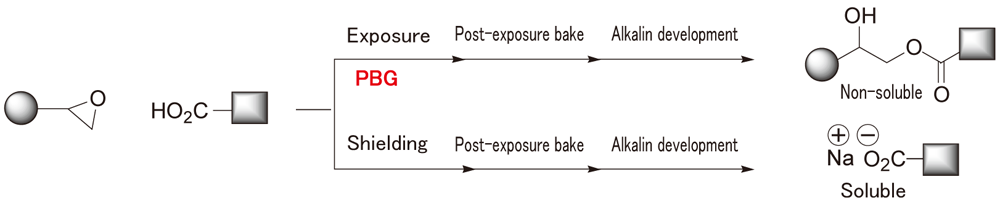

Example of Use 2Patterning by epoxy oligomer × carboxylic acid

Conditions

| Preparation | Mix 1-10 parts of WPBG-345, 0.2-2 parts of 2-isopropylthioxanthone (0.2 equivalent amount to WPBG), and 100 parts of jER®828 (epoxy equivalent of 185, Product of Mitsubishi Chemical Corporation) and 64 parts of Joncryl®682 (OH equivalent of 138, Product of BASF Japan Ltd.) into 300 parts of γ-butyrolactone. |

|---|---|

| Film-forming | Polycarbonate, film thickness: 10-20 μm |

| Exposure | Optional (Illuminance: 5mW/cm2 (254 nm), 100 mW/cm2 (365 nm), and 261 mW/cm2 (405 nm)) |

| Post-exposure bake | 150°C/10 minutes |

| Development | 1 wt% Na2CO3, Immerse for 1 minute → rinse with water. |

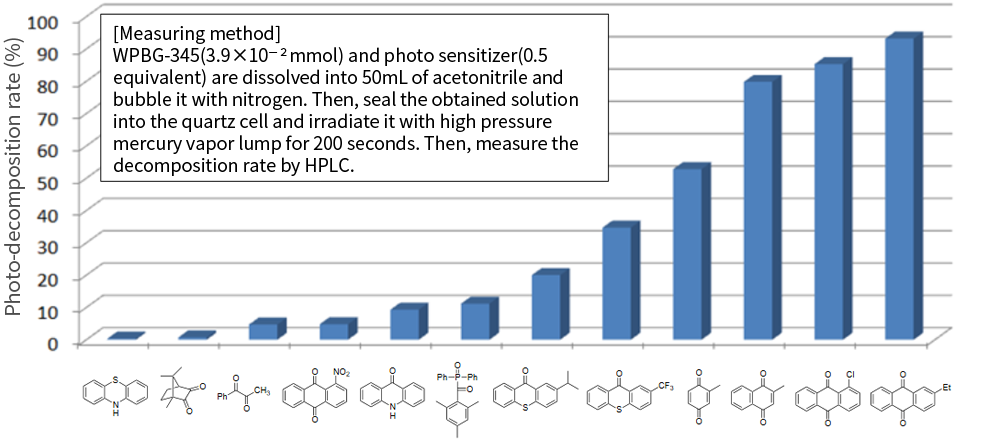

Photo sensitizer effective for borate-type photo base generators (PBG)

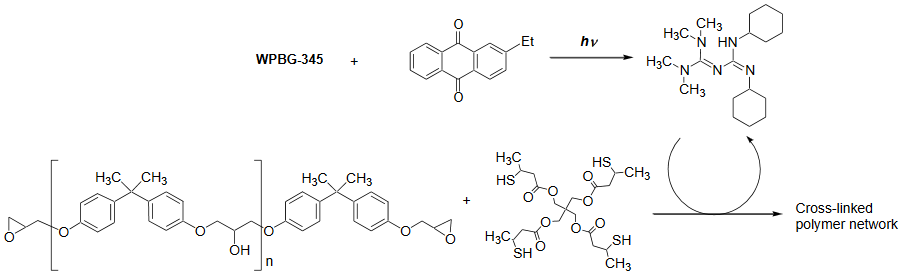

WPBG-300 and WPBG-345 can generate alkyl biguanide under a wide range of wavelength by used with photo sensitizers such as thioxanthone which can be absorbed in long-wavelength (Fig.1). Since photodegradability of PBG changes depending on the type of photo sensitizer, it is necessary to select the optimal sensitizer by taking into consideration the light source, coloration after curing and other conditions.

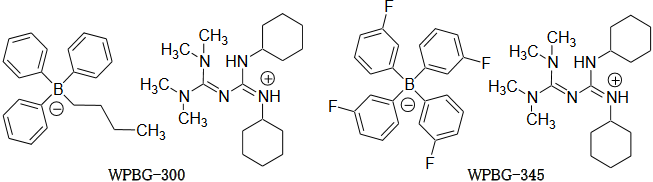

Fig.1 Structural formulas for WPBG-300and WPBG-345

Fig.1 Structural formulas for WPBG-300and WPBG-345

Fig.2 shows the photo-decomposition rate when WPBG-345 is used combined with different photo sensitizers.

2-Ethylanthraquinone and 1-Chloroanthraquinone show high photo sensitizing effect and contribute to improvement of photodegradability of WPBG-345.

Fig.2 Change of photodegradability of WPBG-345 depending on different photo sensitizers

Fig.2 Change of photodegradability of WPBG-345 depending on different photo sensitizers

To use 2-Ethylanthraquinone as a photo sensitizer for epoxy oligomer/multifunctional thiol makes the curing time shorter than to use 2-Isopropylthioxanthone. Similarly, to use 2-Ethylanthraquinone for WPBG-300 makes the photodegradability improved.

Fig.3 Anionic UV curing of epoxy oligomer and polyfunctional thiol

Fig.3 Anionic UV curing of epoxy oligomer and polyfunctional thiol

Mix 3-10 parts of WPBG-345, 0.2-1 parts of sensitizer, and 100 parts of jER®828 (epoxy equivalent of 185, Product of Mitsubishi Chemical Corporation), and heat or use a diluent to promote dissolution. Mix 70 parts of KarenzMT®PE1 (SH equivalent of 138.5, Product of Showa Denko K.K.) at room temperature. Irradiate for 10 seconds (Illuminance: 5mW/cm2 (254 nm), 100 mW/cm2 (365 nm), and 261 mW/cm2 (405 nm)), and heat at 120℃.

Contact us for more details.

We are waiting for questions and requests on products.